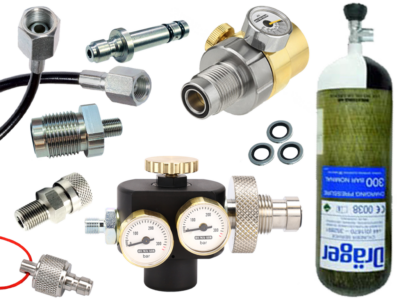

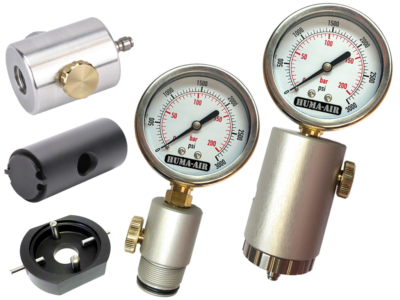

Huma Air: Regulators And Tuning Parts For Airguns

Huma-Air was founded in the Netherlands in 2015 by Huub and Marc (hence the name), two passionate air gunners with a heart for technics, making air regulators, tuning parts and moderators widely available for enthusiastic air shooters all over the world.

By working closely with many air rifle shooters and listening to the feedback of our customers, we always try to develop new and innovative after market products to customize and improve your air rifle for the ultimate shooting experience.

Our technical team is always open to discuss any question or to have a brainstorm to improve your air rifle.

-

Worldwide shipping

-

We strive to dispatch orders placed before 14.00 (GMT+1) the same day